Heat Treatment

The heat treatment department is Ofar excellence.

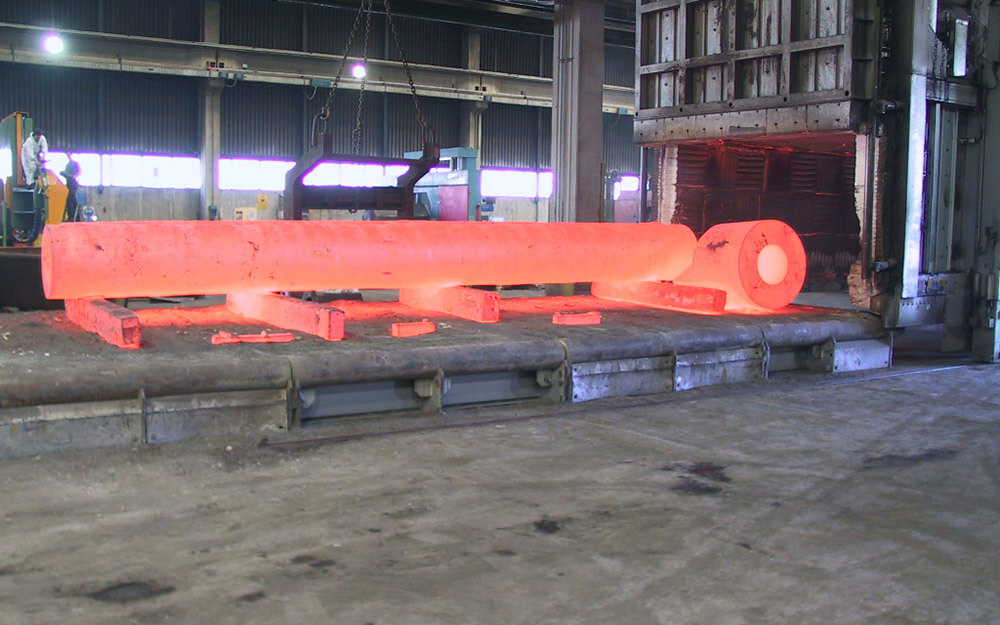

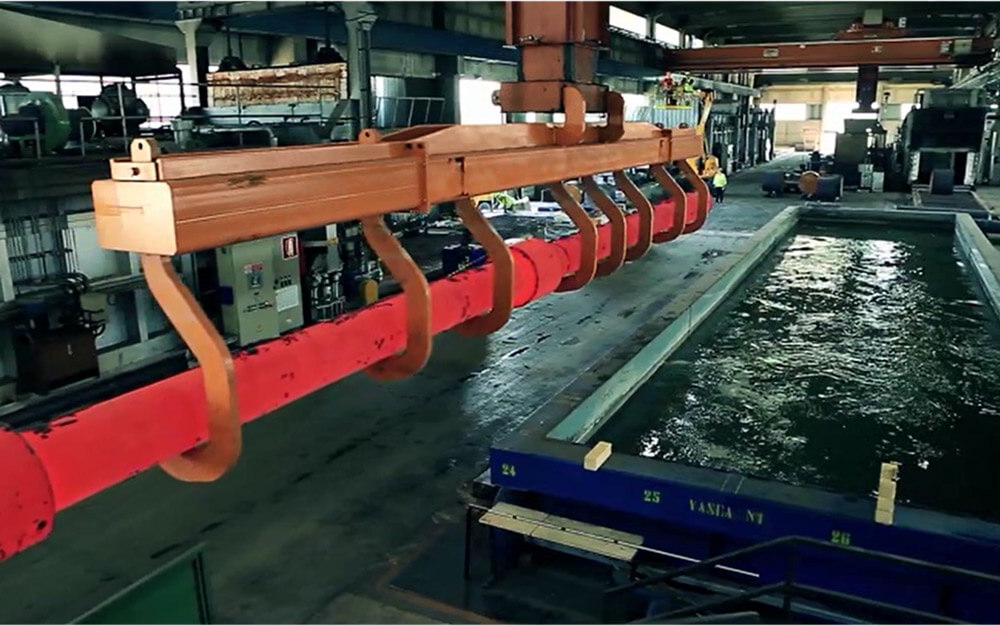

The department holds traditional bell horizontal furnaces and water/polymer tanks up to 28 m in length.

Three drop-bottom furnaces provide special equipment for products requiring very short transfer time or production with consistent number of items undergoing the very same heat treatment.

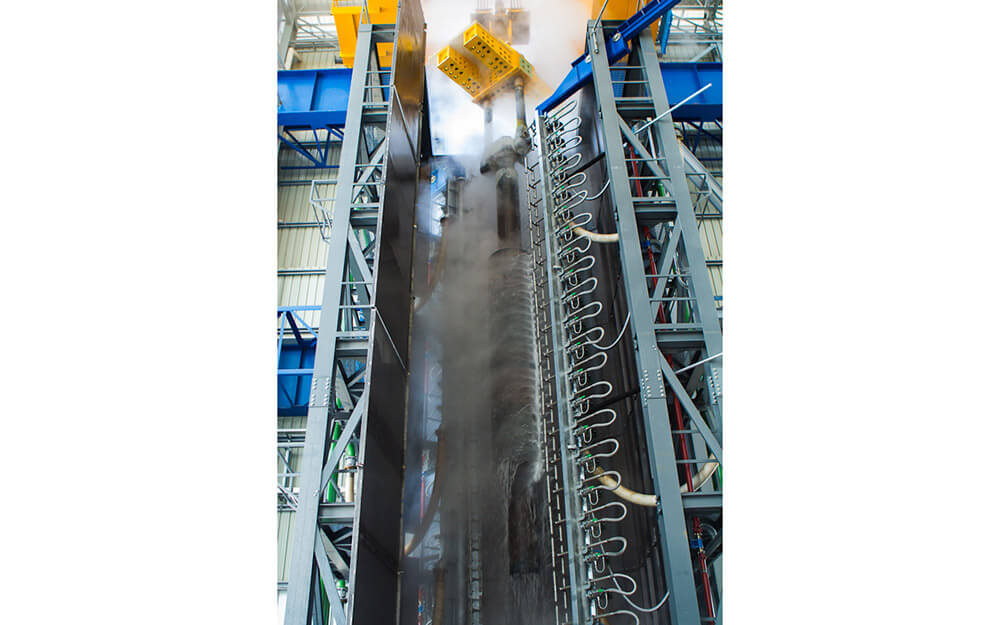

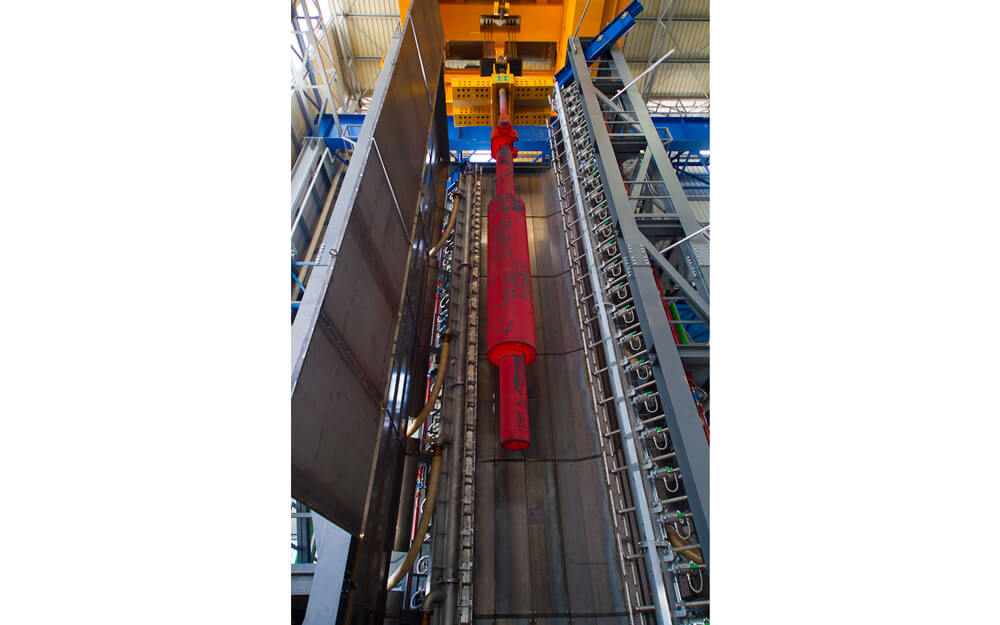

Two vertical furnaces suitable for shafts up to 16 meters aim to minimize the deformation of long products during HT. Those are coupled with a vertical water spray quenching facility able to specifically regulate the quenching effect on the different item sections through the regulation of water nozzles.

Heat treatments:

- Annealing

- Normalizing

- Solutioning

- Quench and tempering

- Vertical spray quenching

- Tempering and stress relief